Dual Handle Commercial Industrial Kitchen Faucet Sprayer Short Type Pre-Rinse Hot Cold Water Stainless Steel Wall Mount 2 Holes

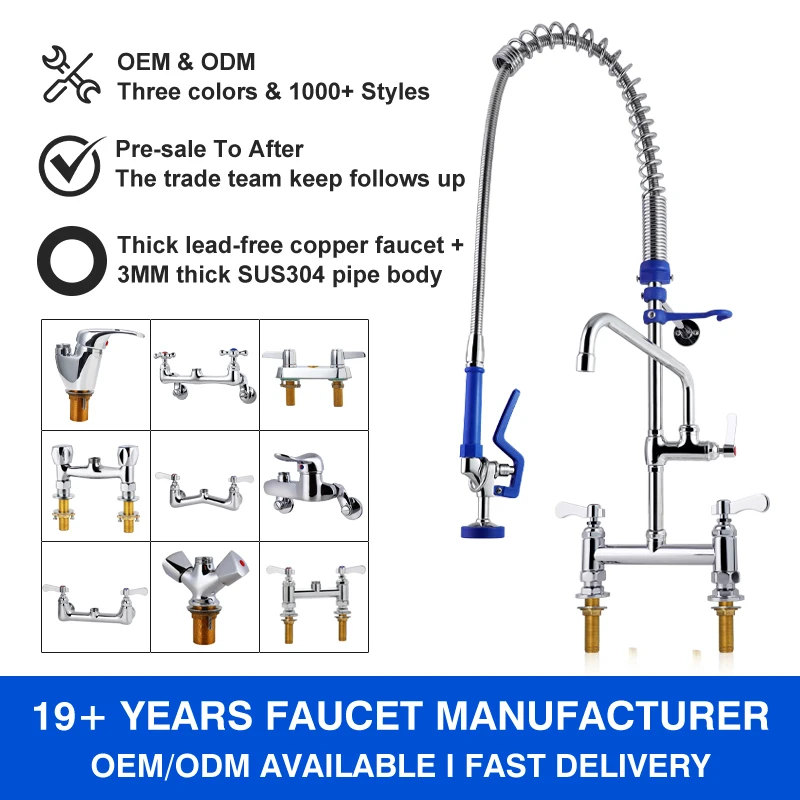

OEM & ODM:Three colors & 1000+ Styles

Pre-sale To After:The trade team keep follows up

Thick copper faucet +:3MM thick SUS304 tube body

- PRODUCT DETAILS

PRODUCT DETAILS

Product Description

Product Description

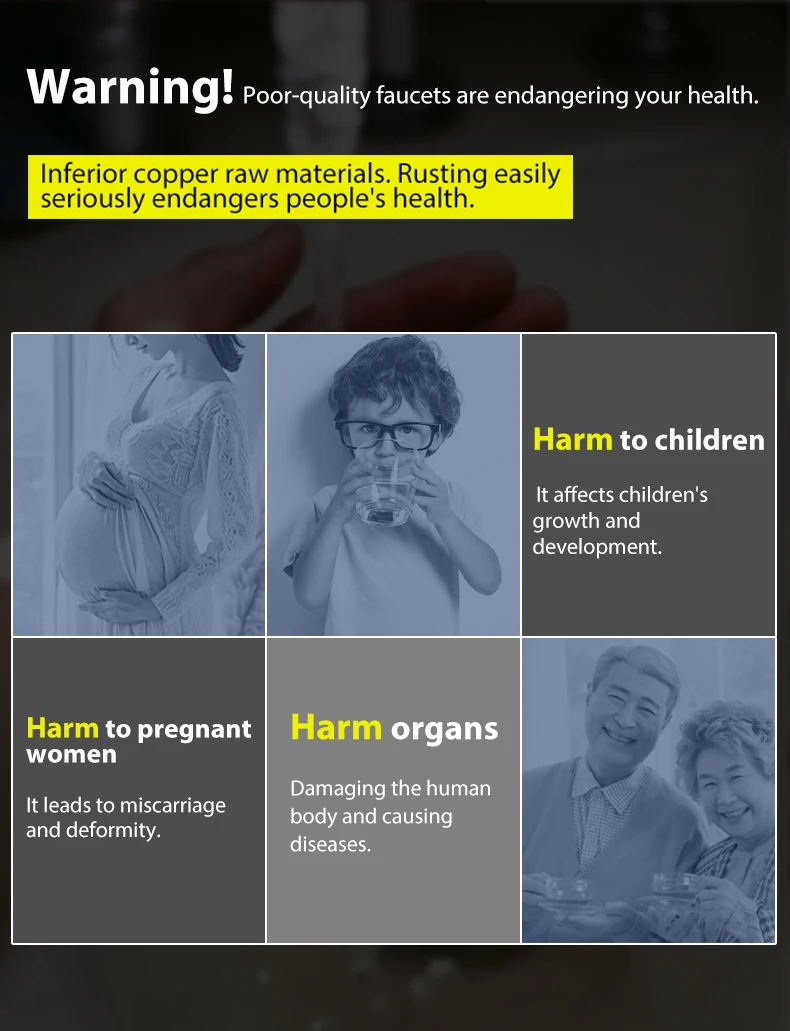

The Dual Handle Commercial Industrial Kitchen Faucet Sprayer Short Type Pre-Rinse Hot Cold Water Stainless Steel Wall Mount 2 Holes is a rugged, space-efficient fixture engineered to meet the uncompromising demands of industrial and commercial kitchens—from high-volume restaurants and manufacturing facilities to institutional food service hubs and industrial cleaning stations—where durability, compact functionality, and precise control are non-negotiable. Designed with an industrial aesthetic and practicality at its core, this faucet stands out with its key features: dual handles, short-type spout, integrated pre-rinse sprayer, wall-mounted 2-hole installation, and premium dual-material construction that prioritizes long-term reliability in harsh environments. At its foundation, the faucet boasts a robust build: a thick copper faucet combined with a 3MM thick SUS304 stainless steel tube body, a combination carefully selected to withstand the rigors of industrial use. The 3MM thick SUS304 stainless steel tube body serves as the structural backbone, offering exceptional resistance to corrosion, rust, and mechanical wear—critical properties for spaces exposed to constant hot/cold water cycles, heavy-duty cleaning chemicals, and frequent physical impact. Unlike thinner or lower-grade metals that degrade quickly under industrial stress, this heavy-duty stainless steel maintains its structural integrity and sleek appearance, ensuring consistent performance even in the most demanding conditions. Complementing this sturdy framework is the thick copper faucet component, which delivers both hygienic and functional benefits. Copper’s natural antimicrobial properties actively inhibit the growth of bacteria, mold, and other harmful microorganisms in moist kitchen environments, ensuring water remains clean and safe for food preparation, sanitization, and industrial cleaning tasks—essential for upholding strict hygiene and safety standards in commercial industrial settings. Additionally, copper enhances the faucet’s durability, adding structural rigidity that prevents warping or cracking under pressure, even during heavy use of the pre-rinse sprayer.

A defining feature of this faucet is its short-type spout design, which offers exceptional space efficiency for compact commercial industrial kitchens or areas with limited vertical clearance. The shortened spout minimizes the faucet’s footprint, making it ideal for tight workspaces, under-counter installations, or cleaning stations where overhead space is restricted. Despite its compact size, the short spout delivers optimal water coverage for daily tasks—from rinsing small to medium cookware and utensils to sanitizing countertops and equipment. The spout’s streamlined design also reduces splashing, directing water precisely where it’s needed and keeping surrounding areas dry. Paired with the short spout is the integrated pre-rinse sprayer, a critical tool for industrial kitchen efficiency. The sprayer delivers a powerful, concentrated jet stream that cuts through tough grease, food residue, and industrial grime on pots, pans, and equipment—reducing the time and effort required for pre-washing and deep cleaning. The sprayer head is engineered for industrial-grade durability, with a responsive trigger that allows for one-handed operation, enabling staff to multitask or maintain a secure grip on heavy equipment while cleaning. The flexible, kink-resistant sprayer hose extends the faucet’s reach, ensuring thorough cleaning of hard-to-reach areas without compromising the faucet’s compact design. When not in use, the sprayer docks securely to the spout, maintaining a neat and organized workspace—critical for industrial environments where clutter can hinder productivity and safety.

The wall-mounted 2-hole installation is another key functional highlight, designed for stability and space optimization in industrial settings. Wall mounting frees up valuable countertop and sink deck space, allowing for more efficient use of work areas and simplifying cleaning around the sink. The 2-hole configuration ensures secure, balanced placement, minimizing movement during heavy use and providing a solid base for the dual handles and pre-rinse sprayer. This installation method also reduces the risk of leaks by creating a direct, stable connection to plumbing lines—essential for industrial kitchens where water waste or equipment damage from leaks can be costly. The wall-mounted design further enhances safety by eliminating tripping hazards associated with countertop-mounted fixtures, making it suitable for high-traffic industrial environments.

The dual-handle control system offers precise, independent regulation of hot and cold water, a critical feature for industrial kitchen tasks that require specific temperature control. Each handle is ergonomically designed with a textured, industrial-style grip, ensuring a secure hold even when hands are wet, greasy, or gloved—reducing the risk of slips in fast-paced industrial settings. The dedicated hot and cold handles allow staff to quickly adjust water temperature and flow rate to suit specific tasks: cold water for rinsing produce or cooling equipment, warm water for handwashing, or hot water for sanitizing dishes and industrial tools. This precise control eliminates the need for time-consuming fine-tuning, reducing water waste and improving operational efficiency. The handles are built with industrial-grade components, ensuring smooth operation and resistance to wear even after thousands of uses.

Customization is a core strength of this industrial faucet, with comprehensive OEM & ODM services that cater to the unique needs of commercial industrial operators. Customers can choose from three carefully curated color options, each designed to withstand industrial wear and enhance the faucet’s rugged aesthetic: a polished stainless steel finish for a classic industrial look, a matte black finish for a modern, sleek edge, and a brushed brass tone that adds warmth without compromising durability. Beyond color choices, the faucet offers over 1000 styles, encompassing variations in handle design (lever-style, knob-style, or industrial grip), spout length (adjusted short-type options), and sprayer head design (high-pressure or multi-mode). This extensive range ensures that whether the space is a compact industrial kitchen, a large manufacturing facility, or a specialized cleaning station, there is a style that aligns with the environment’s functional requirements and aesthetic. For businesses seeking even more tailored solutions, OEM & ODM services enable custom modifications—such as adjusted handle placement for ergonomic efficiency, specialized spray patterns for industrial cleaning tasks, or branded engravings—ensuring the faucet perfectly matches unique operational needs and brand identity.

Supporting the faucet throughout its lifecycle is a dedicated pre-sale to after-sale service system managed by a professional trade team. During the pre-sale phase, the team works closely with customers to understand their specific industrial requirements, including space constraints, usage patterns, and functional priorities, providing expert guidance on color selection, style choices, and customization options. They share detailed technical specifications, including installation requirements, flow rates, pressure compatibility, and sprayer performance, helping customers make informed purchasing decisions that align with their industrial needs. Once an order is placed, the trade team maintains proactive communication during the mid-sale phase, updating customers on manufacturing progress, quality checks, and delivery timelines. This transparency eliminates uncertainty, allowing customers to plan installation around production schedules and minimize disruptions to industrial operations. Post-sale, the support continues: the team provides detailed installation guides tailored to the wall-mounted 2-hole design, offers troubleshooting assistance for any operational issues (such as handle adjustments or sprayer pressure calibration), and ensures access to industrial-grade replacement parts (such as spray heads, hoses, valves, or handles) if needed. Whether customers have questions about maintaining the faucet’s finish in industrial environments or optimizing the pre-rinse sprayer’s performance for heavy-duty cleaning, the trade team delivers timely, reliable support to keep the faucet functioning optimally.

Product Advantages

One of the most compelling advantages of this faucet is its exceptional industrial-grade durability and long-term reliability, driven by its thick copper and 3MM thick SUS304 stainless steel construction. In commercial industrial kitchens where faucets are subjected to constant use, heavy impact, and exposure to harsh chemicals, durability is non-negotiable—and this model is built to withstand the test of time. The SUS304 stainless steel’s resistance to corrosion, rust, and chemical damage ensures the faucet remains in top condition even when exposed to industrial cleaning agents, high humidity, and constant water flow, preventing unsightly damage and extending its lifespan. The thick copper component adds structural rigidity, reducing the risk of bending, cracking, or leaking—common issues with cheaper faucets made from thin metals or plastic parts that fail under industrial stress. Unlike traditional commercial faucets that require frequent replacement due to wear and tear, this model minimizes downtime and replacement costs, making it a cost-effective long-term investment for industrial operators. Additionally, the high-quality materials ensure the faucet maintains its rugged industrial aesthetic over time, avoiding the faded or worn look that can undermine the functionality and appearance of industrial spaces.

The short-type spout and wall-mounted 2-hole design deliver unmatched space efficiency, a critical benefit for compact commercial industrial kitchens and high-traffic areas. The shortened spout reduces the faucet’s vertical and horizontal footprint, making it ideal for spaces with limited overhead clearance, under-counter installations, or crowded workstations. This space-saving design allows for more efficient use of available workspace, enabling staff to move freely around the sink and access equipment without obstruction. The wall-mounted 2-hole installation further optimizes space by eliminating the need for countertop or sink deck mounting, freeing up valuable surface area for food preparation, equipment storage, or industrial cleaning tasks. For industrial facilities where space is at a premium, this compact design is a game-changer, offering full functionality without sacrificing workspace efficiency.

The dual-handle control and integrated pre-rinse sprayer enhance operational efficiency and precision, key advantages for busy industrial kitchens. The dual-handle system allows for independent control of hot and cold water, enabling staff to quickly achieve the exact temperature and flow rate needed for each task—whether sanitizing at high temperatures, rinsing with cold water, or adjusting for handwashing. This precision reduces water waste and ensures consistent results, critical for industrial processes that require adherence to strict hygiene standards. The pre-rinse sprayer’s powerful jet stream cuts through tough grease, grime, and industrial residue in seconds, reducing the need for manual scrubbing and saving valuable time during cleaning and pre-washing tasks. The one-handed trigger operation of the sprayer further enhances efficiency, allowing staff to multitask or handle heavy equipment while cleaning. In high-volume industrial settings, this efficiency translates to faster task completion, smoother workflows, and reduced staff fatigue during long shifts.

The industrial aesthetic and rugged design offer both functional and visual advantages for commercial industrial environments. Aesthetically, the faucet’s sleek, industrial-style design complements the decor of industrial kitchens, manufacturing facilities, and cleaning stations—featuring clean lines, durable materials, and a no-nonsense appearance that aligns with industrial design themes. Unlike decorative faucets that feel out of place in industrial settings, this model blends seamlessly, enhancing the professional, functional look of the space. Functionally, the rugged design ensures the faucet can withstand the physical demands of industrial use—from accidental impacts with equipment to frequent handling by gloved staff. The textured handles and durable sprayer head are built to resist wear and tear, ensuring reliable performance even in the most demanding industrial conditions.

Extensive customization options give this faucet a unique edge in meeting diverse industrial needs. With three color options, over 1000 styles, and comprehensive OEM & ODM services, the faucet can be tailored to align with any commercial industrial environment’s functional requirements and aesthetic. The color options allow businesses to match the faucet to their facility’s decor or brand identity—whether opting for stainless steel for a classic industrial look, matte black for a modern edge, or brass for a touch of warmth. The 1000+ styles ensure compatibility with different industrial setups, from compact cleaning stations to large-scale food processing facilities. The OEM & ODM services take customization further, enabling businesses to request specific modifications—such as adjusted sprayer pressure for industrial cleaning, ergonomic handle designs for extended use, or specialized flow rates for water conservation—ensuring the faucet is not just a generic tool but a tailored solution that supports the specific workflow of each industrial facility.

Hygiene and safety are standout advantages of this faucet, addressing critical concerns in commercial industrial settings. The copper component’s natural antimicrobial properties inhibit the growth of harmful bacteria like E. coli and Salmonella, reducing the risk of cross-contamination and helping businesses maintain compliance with strict industrial hygiene regulations. The smooth, non-porous surfaces of SUS304 stainless steel and copper are easy to clean and sanitize, as they do not trap dirt, grease, or germs—unlike faucets with crevices or textured surfaces that can harbor contaminants in industrial environments. This simplifies maintenance and ensures a hygienic environment for staff and products alike. Additionally, the wall-mounted design reduces water splashing and eliminates countertop gaps where moisture and debris can accumulate, further enhancing hygiene and reducing the risk of slip-and-fall accidents—a leading cause of workplace injuries in industrial settings. The ergonomic handles also reduce the risk of strain or fatigue, promoting a safer working environment for staff during long industrial shifts.

Finally, the comprehensive pre-sale to after-sale support enhances the overall value of this faucet, providing peace of mind for industrial operators. The pre-sale guidance helps businesses select the right configuration for their specific needs, avoiding costly mistakes such as choosing a faucet with insufficient sprayer pressure or incompatible mounting hardware. Mid-sale updates keep operators informed about order progress, allowing them to plan installation around production schedules and minimize disruptions. Post-sale support ensures that any issues—whether installation questions, operational problems, or replacement part needs—are resolved quickly, minimizing downtime and keeping industrial operations running smoothly. This end-to-end support builds trust and confidence, making the faucet a reliable investment that industrial operators can depend on for years to come. Whether used in a busy industrial kitchen, a manufacturing facility, or a specialized cleaning station, this dual-handle, short-type faucet delivers the durability, functionality, and space efficiency that commercial industrial environments demand.

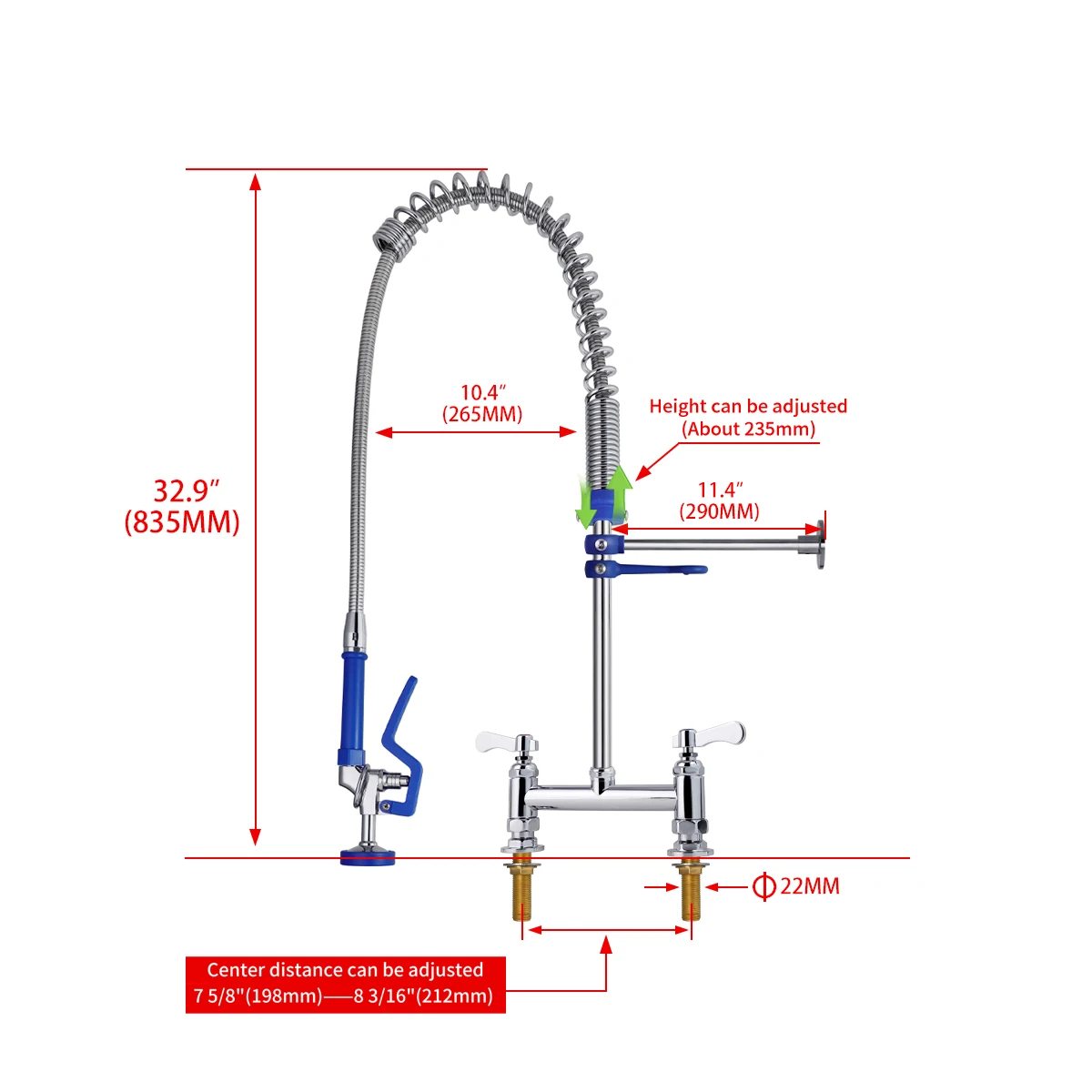

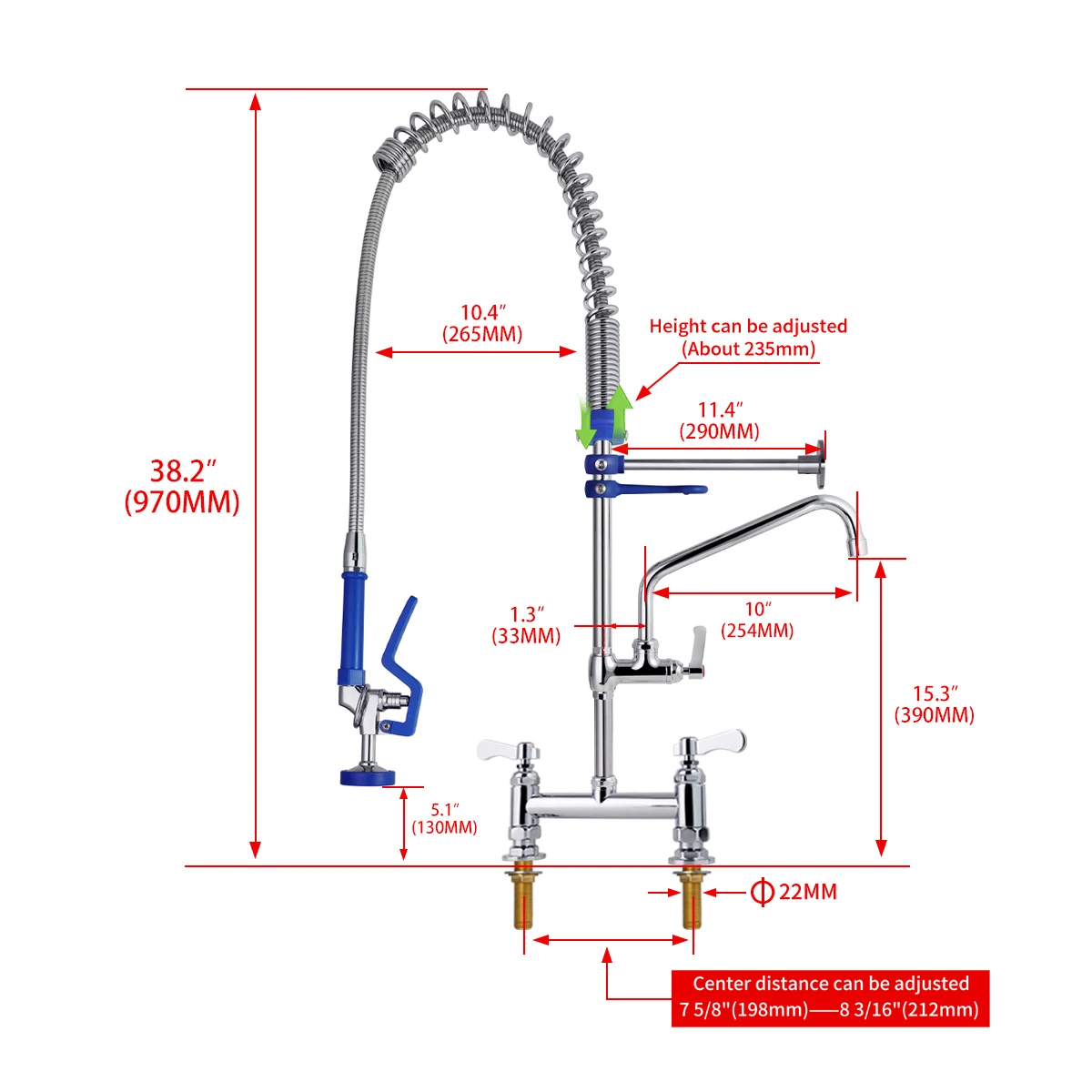

The above data is manually measured and may have certain deviations. For precise dimensions, please contact us

Packing & Delivery

It is packaged with similar materials. For specific details, please contact us to obtain specific pictures

FAQ

Q1: Are you a trading company?

NO! We’re a manufacturing factory with over 16 years experience.

Q2: Where is your factory?

Our factory is located in Shuikou town,Kaiping,Jiangmen City , 1.5hr drive from Guangzhou. And it’s our pleasure to arrange the pickup in Guangdong.

Q3: Do you offer OEM & ODM service?

Yes , product or packaging all available , we have professional R&D and sales team to understand customers’ needs. For OEM, your brand logo can be lasered onto the product once receipt of your letter of authorization.

Q4: What’s your MOQ and what's the production lead time?

We accept 1pc order , and for order within 200sets , lead time is 7days

Q5: How do your control product quality?

We implement strict quality control system from raw material sourcing to finished products , we send sample products to run test in authorized lab every other months.100% inspection for each shipment before delivery.

Q6: How's lead time and cost of developing new prototype?

Different design, different leadtime and cost. The prototype cost can be refund once total order quantity reach a certain amount.