What Are the Advantages of Using a Commercial Sprayer in Food Prep?

Each part of a commercial kitchen must be prepped quickly, safely, and thoroughly, as the slightest delay or lapse in hygiene can ruin the entire schedule for the day. One of the best time-savers for food prep is a commercial sprayer. Commercial sprayers do more than wash dishes. They help food prep be more efficient, faster, and cleaner. Here are the most important benefits commercial sprayers add to food preparation.

Increasing Food Prep Cleaning Efficiency

Time is the most important factor to consider in food prep. If time wasn’t a factor, food prep would be tedious. For example, rinsing a basket of greens or scrubbing a bowl with dried dough takes a lot of time, and if you have to do that, you will quickly fall behind on other prep tasks needed for orders. If you have a low-quality sprayer, the time wasted will increase, as the water flow will be weak and messy sprayers will create more work with spills that you have to clean. All of this will add considerable time to your food prep tasks.

Every commercial sprayer has high-pressure settings that eliminate grime in seconds. For instance, a mixing bowl that took two minutes to scrub clean can now be rinsed with a strong spray in just 30 seconds. This timing is crucial if you are preparing dozens of ingredients; these few minutes can be spent on chopping, mixing, or even cooking. Some sprayers do have anti-clogging features which are a big advantage in a kitchen that uses hard water. Mid prep, you don’t have to stop to unclog a spray that is blocked by mineral deposits. This feature is a priceless time saver when you are all set to prep ingredients.

The sprayer's design can also make a difference in efficiency. The pull-down or pull-out sprayer lets you get every corner of large pots or deep sinks without repositioning the container. If you need to rinse a large pot of potatoes, you can simply pull the sprayer over the sink instead of carrying the pot to the faucet. Wall-mounted or deck-mounted positions are tailored to the exact location you need, such as next to the prep table or by the sink, minimizing the distance you need to walk across the kitchen to grab a sprayer. These design aspects greatly reduce the effort needed to clean the workspace while prepping meals.

Upgrading Hygiene for Safety Compliance

The safety of food in any commercial kitchen is unquestionable. Health violations or foodborne illnesses can arise from as little as a bacterium that is present on a prep tool or ingredient. A commercial sprayer effectively eliminates prep areas that remain clean and hygienic in ways that basic tools can’t.

To start with, the quality of the materials is important too. Top-of-the-line commercial sprayers can be constructed using 304 stainless steel, copper, or chrome-plated copper. These materials are not bacteria traps, unlike plastic, which suffers fine fissures wherein germs can hide. After use, stainless steel or chrome can be easily wiped with a sanitizer due to their smooth surfaces. After rinsing a cutting board, you can spray the sprayer with sanitizer and wipe it, ensuring there are no hidden spots for bacteria to grow. This is important in food preparation, where cross-contamination with raw ingredients and germs is a major risk. raw veggies, and meat.

The hygiene of the spray pattern is in the design too. A concentrated spray provides better control, which means the water goes where it is intended, and not all over the prep area. If you are rinsing a head of lettuce, the water won’t splash on the knives and bowls that are clean, and that is not there to be rinsed. This is to avoid recontamination of the tools that were sanitized already. In addition, many commercial sprayers are water efficient, which means that you are not using water that will be wasted and will dilute sanitizers, or leave stagnant water, which is a breeding ground for germs, in the sink.

The Flexibility of a Commercial Sprayer

Food preparation involves multiple tasks. You might be rinsing delicate greens, washing root vegetables and even cleaning tough baking sheets. Since different tasks require different approaches, not every tool out there will be effective. However, a commercial sprayer is versatile enough to meet different food prep needs.

The ability to change different spray patterns is what makes a commercial sprayer useful. For instance, a gentle spray is perfect for rinsing delicate ingredients, such as spinach or berries and will not damage or bruise the produce. Conversely, the powerful jet setting is ideal for cleaning tough surfaces, such as a baking sheet that has burnt batter or a prep table that has stubborn flour. This versatility eliminates the need for multiple tools. You can use a commercial sprayer to rinse food and then use it to clean.

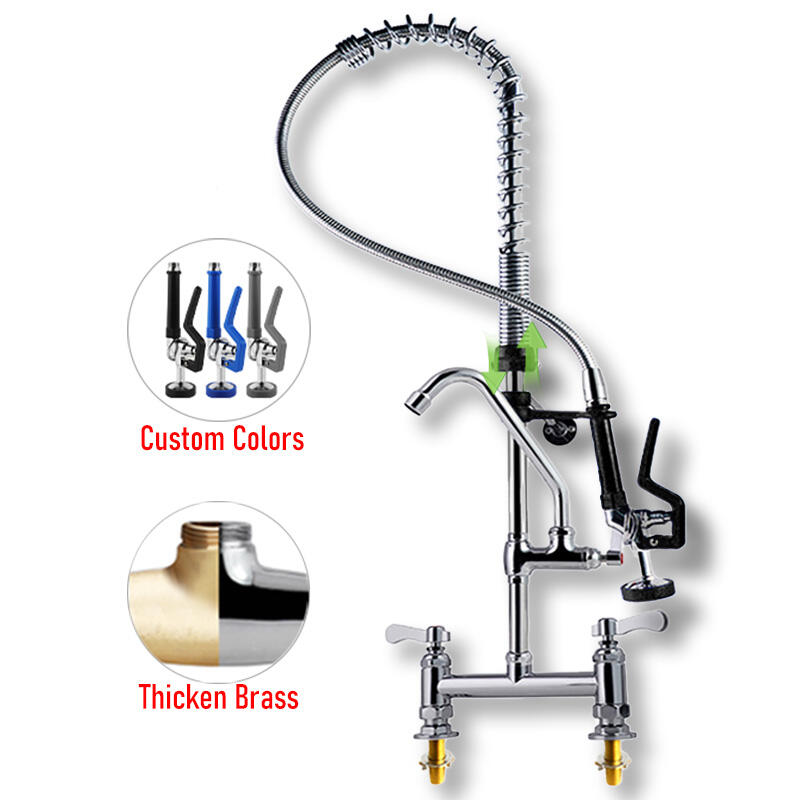

There are also different sizes and types of sprayers which allow for more customization. Some kitchens have small prep areas and in these cases a small, compact, deck-mounted sprayer is a perfect fit since it doesn’t take up too much space. Other kitchens have large industrial sinks which need a sprayer that has a longer flat pipe so that it can reach every part of the sink. Some makes even let you request custom lengths for the pipe so that the sprayer can be designed for the exact prep area. If a sink is a sprayer is a wall-mounted, the wall can be positioned to allow for the sprayer to be placed exactly above the table. This makes it easier to rinse while chopping, which is perfect for prep work. This type of customization allows the sprayer to be designed for the actual user needs rather than forcing the user to adjust to the sprayer.

A Quality Commercial Sprayer is an Investment for the Kitchen, Not an Expense

Kitchens will continue to save more money in the long run when they invest in a good commercial sprayer. A commercial grade tool that is able to go through a lot of wear and tear and is resource efficient will save money in the long run.

The best way to save on costs is to buy durable products. Quality commercial sprayers are made of thick stainless steel or even solid copper so they are designed to withstand abuse and not break. They are ok with getting bumped into by busy employees and having hot water run through them over and over every shift. Quality commercial sprayers also have much longer replacement cycles than cheap plastic ones which need to be replaced every 6 months. When sprayers break down, it leads to expensive replacements. For fast food prep, it is important to minimize downtime as every minute wasted reduces profit. Overall, durable products save money because they save downtime.

Saving money is always a plus, and we can be efficient with water, too. Washing, rinsing, and sanitizing food prep tools consumes a large amount of water. A commercial sprayer with adjustable water flow rates can use less water than a standard tap or a cheap sprayer. Consider a sprayer that consumes 1.5 gallons per minute. Over the course of a month, that is a difference of hundreds of gallons when compared to a sprayer that consumes 2.5 gallons per minute. This is especially beneficial to the bottom line of commercial kitchens, and saves money on bills. Less hot water usage also means that water heaters do not have to work as hard, cutting down on energy expenses. Over time these expenses can be far greater than the initial cost of sprayers.